STM

STM, Sill Trough Membrane… is a high performance self adhering membrane for use as a pan flashing in rough openings of windows and doors prior to their installation. Baywest STM utilizes a high tack, pressure sensitive adhesive combined with a tri layer engineered film. It’s designed to be applied in low temperatures without the use of primer or mechanical fasteners.

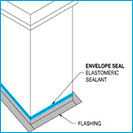

envelopesealant

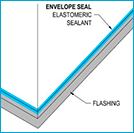

Envelope Seal bonds directly from the flange of the window or door to the substrate of the building whether it be OSB, plywood, or fiberglass board. The excellent adhesion of the product to most surfaces ensures that no moisture or air will penetrate the opening. Furthermore, the product’s elastomeric properties allow it to move and stretch with any building settling making for a permanent seal.

Envelope sealant… the Blue Goo… adheres to many surfaces, forming a closed bond wherever it’s applied. Its elastomeric properties allow it to stretch and move naturally the building. Cold weather testing allows us to operate throughout the tough Prairie winter.

The Canadian Mortgage and Housing Corporation (CMHC) has determined that the window to wall interface is the major contributor to moisture problems in buildings. Envelope Seal is an elastomeric co-polymer thermal plastic that acts as a primary barrier to moisture and air penetration at the window to wall interface. Its physical properties allow it to adhere to most surfaces while staying flexible over a wide range of temperatures. These characteristics enable the product to move and adjust with building settling, while maintaining a watertight seal around building openings. Use of Envelope Seal is part of the Built Green initiative, and contributes to reducing new home warranty claims while improving air tightness by as much as 43%.

Wall Wrap

Baywest STM (Sill Trough Membrane) is a high performance self-adhering membrane for use as a pan flashing in the rough openings of windows and doors. Baywest STM utilizes a high-tack, pressure sensitive adhesive combined with a tri-layer engineered film. The proprietary facer combines a UV protection layer with a reinforcement layer providing puncture and tensile strength along with a waterproof tie-in layer that adds additional bond strength to the adhesive. STM is designed to be applied at temperatures as low as -28c without the use of primer or mechanical fasteners. The membrane is self-sealing and forms a positive seal around properly installed anchors such as nails, screws, and staples.

For more information please download the brochure below.

Basement Window

Envelope Sealant, a National Building Code compliant product with CCMC approval, is a single component, non-sag elastomeric polymer, designed for use in most moving and non-moving joints. Envelope Sealant forms a closed bond wherever applied, securing your windows and doors from unwanted moisture build-up. No water. No mold. No damage. The Blue Goo adheres to many surfaces, including vinyl, wood, concrete, and metal. Its elastomeric properties allow it to stretch and move naturally with the building, maintaining a perfect seal over time. Envelope Sealant requires no primer, no cutting or stapling, and offers year-round adhesion. Envelope Sealant is backed by a comprehensive 7-year warranty protection plan, providing consumers peace of mind. Find out how to better protect every home and maximize window performance while offering buyers greater value for their money.

For more information please download the brochure below.

Winter Tested

The Alberta Research Council has conducted two sets of tests in order to determine the low temperature flexibility and tensile resilience of Envelope Seal. These tests both indicated that Envelope Seal has excellent elongation and flexibility at extreme sub-freezing temperatures.

Browse through the pictures on the right to view highlights from the two reports, or download the reports in their entirety below. Envelope Seal was also tested by EnerVision to determine the extent to which it aids in air tightness. It was found that Envelope Seal can improve air tightness by as much as 43% when compared to other window/door preparations.

WEATHER WRAP SYSTEM

Baywest Projects has developed an exterior moisture management system designed to meet the requirements implemented by the City of Edmonton. As of March 31, 2007 all houses are to have a weather resistant exterior prior to the insulation and vapor barrier inspection.

The Baywest system addresses all horizontal seams and wall-to-roof flashings. This system is recognized by the City of Edmonton as being a very good example of how to protect the building while preventing moisture from getting into the interior insulation. This moisture management system, in combination with Envelope Seal treatment to the building openings, is an excellent way to ensure a dry, comfortable interior.

UPPER FLOOR INTERSECTION

MAIN FLOOR INTERSECTION

SHEATHING INTERSECTION

WALL TO ROOF INTERSECTION

BOXOUT TO ROOF INTERSECTION

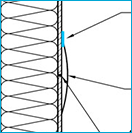

TYVEK IS EMBEDDED INTO THE ENVELOPESEALANT TO ENSURE PROPER WATER SHED.